Mkpuchi PVD

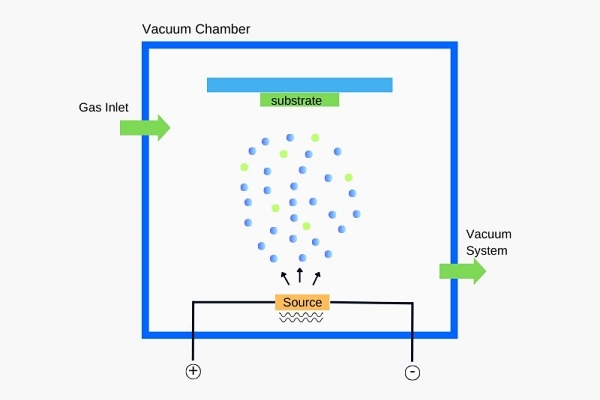

Teknụzụ PVD (Nkwakọba Vapor anụ ahụ) na-ezo aka na teknụzụ nke na-eji ụzọ anụ ahụ n'okpuru ọnọdụ agụụ na-eme ka isi mmalite ihe dị n'ime atom ma ọ bụ ụmụ irighiri ihe, ma ọ bụ tinye ha n'ime ion, ma tinye obere ihe nkiri nwere ụfọdụ ọrụ pụrụ iche n'elu mkpụrụ. .

PVD technology bụ isi n'elu ọgwụgwọ technology n'ọtụtụ ebe na elu mgbanwe, functionalization, ịchọ mma, wdg nke ihe dị iche iche ọrụ.

Ụzọ ndị bụ isi e si ewepụta uzuoku anụ ahụ gụnyere:

›Vacuum evaporation

›Ihe mkpuchi na-agbasa

›Ihe mkpuchi plasma Arc

›Mkpuchi ion

Anyị na-enyeThermal evaporationnaIgwe ọkụ eletrik evaporationihe ndị metụtara ya, gụnyere elektrọn beam crucible liners, tungsten evaporation filaments, eletrọn egbe tungsten filaments, ụgbọ mmiri, ihe evaporation, wdg.

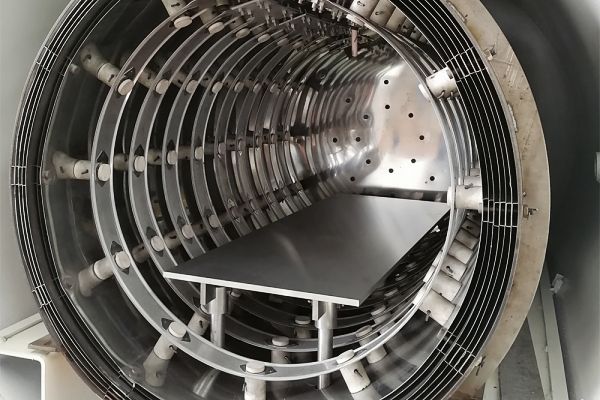

Igwe ọkụ ọkụ

A na-ejikarị ọkụ ọkụ seramiiki eme ihe, ịgbaze oghere, akụkụ ọkụ eletrik degassing, annealing, metal part brazing, seramiiki-metal sealing, physical vepor deposition (PVD), wdg.

Anyị na-enye ihe ndị na-ekpo ọkụ, ụgbọ mmiri na ndị na-ebu, ihe mkpuchi ọkụ, crucible liners, tungsten wires, na evaporation source, nhazi akụkụ, fasteners, wdg. Ihe ndị ahụ bụ tungsten, molybdenum, ma ọ bụ tantalum, nke nwere ike ịhazi ya.

Fotovoltaic & Semiconductor

Igwe ọkụ silicon nke otu kristal, nke a makwaara dị ka ọkụ ọkụ silicon kristal ma ọ bụ ọkụ ingot silicon, bụ ngwa pụrụ iche ejiri na ụlọ ọrụ fotovoltaic na semiconductor iji mepụta ingots silicon otu-kristal dị elu.

Silikoni Monocrystalline bụ ihe bụ isi maka imepụta ngwaọrụ semiconductor dị ka sekit agbakwunyere (ICs), sel anyanwụ, na sensọ.

"Usoro Czochralski" bụ usoro a na-ejikarị eme ihe ugbu a maka ịkwado otu silicon silicon.

Anyị na-enye mkpanaka mkpụrụ molybdenum, tungsten na molybdenum crucible liners, fasteners, molybdenum hooks, tungsten carbide hammers, wdg.

Glass na Ụwa dị ụkọ

›Ụlọ ọrụ Glass

Anyị na-enye molybdenum electrodes maka iko agbaze.

Ihe elektrọn molybdenum anyị bụ mkpanaka molybdenum dị 99.95% dị elu.

Molybdenum electrode size: φ20-152 * L (otu: mm), anyị nwere ike inye ihe alkali-asa elu elu, mechanically polished elu, wdg.

›Ụlọ ọrụ na-adịghị ahụkebe ụwa

Ụlọ ọrụ ụwa na-adịghị ahụkebe gụnyere mmịpụta, nhazi, na itinye n'ọrụ nke ihe ndị dị ụkọ n'ụwa, bụ akụkụ dị mkpa nke teknụzụ na ngwa dị iche iche dị elu.

Anyị nwere ike ịnye tungsten, molybdenum, na tantalum kpo oku, tungsten sintered, molybdenum crucibles, graphite crucibles, wdg.

Ngwa & Ngwa igwe

›Igwe diaphragm: A na-ejikarị ya na nlele nrụgide diaphragm na transmitters. Ihe anyị na-emepụta gụnyere SS316L, tantalum, titanium, HC276, Monel400, na Inconel625.

› Eletrọd mgbaàmà: A na-eji ya eme ihe na mita eruba electromagnetic. The electrode size bụ M3 ~ M8, na ihe na-agụnye SS316L, tantalum, titanium, na HC276.

› Eletrọd ala (mgbanaka ala):A na-eji ya eme ihe maka igwe eletrọnịkị, nke a na-ejikarị ụzọ abụọ. Nha si na DN25 ruo DN600, na ihe ndị gụnyere SS316L, tantalum, titanium, na HC276.

›Akara diaphragm: eji kewapụ ihe nha na ọkara. Ihe diaphragm anyị na-emepụta gụnyere SS316L, titanium, HC276, na tantalum. ASME B 16.5, DIN EN 1092-1 na ụkpụrụ ndị ọzọ dị.

› Mgbanaka mgbanaka:eji maka flange-ejikọta diaphragm akara, nke nwere ike wepu sedimenti na diaphragm site na-ekpocha na ihicha.

› tube nchedo thermocouple:eji echebe thermocouples maka ojiji nkịtị na ngwa ụlọ ọrụ dị iche iche. Anyị na-enye tubes nchebe na ihe ndị a: tungsten, molybdenum, na tantalum.

Biko kpọtụrụ anyị ma ọ bụ lelee weebụsaịtị anyị maka nkọwa na ngwaahịa ndị ọzọ.

Kpọtụrụ anyị

Amanda│Onye njikwa ịre ahịa

E-mail: amanda@winnersmetals.com

Ekwentị: +86 156 1977 8518 (WhatsApp/Wechat)

Ọ bụrụ na ị ga-achọ ịmatakwu nkọwa na ọnụ ahịa nke ngwaahịa anyị, egbula oge ịkpọtụrụ onye njikwa ahịa anyị (Amanda), ọ ga-aza gị ozugbo enwere ike (na-adịkarịghị karịa awa 12), daalụ. .