TZM alloy ugbu a bụ ihe kacha mma molybdenum alloy elu okpomọkụ ihe.Ọ bụ ihe ngwọta siri ike nke siri ike na nke na-eme ka molybdenum na-eme ka ahụ dịkwuo ike, TZM siri ike karịa metal molybdenum dị ọcha, ma nwee okpomọkụ recrystallization dị elu na nguzogide dị mma, okpomọkụ recrystallization dị ihe dị ka 1400 Celsius C, nke dị elu maka molybdenum, ọ nwere ike. nye mma solderability.

MHC bụ molybdenum alloy emelitere nke nwere hafnium na carbon.N'ihi na nkesa nke ultrafine carbides dị n'otu, ihe ahụ ka na-egosipụta uru dị na nguzogide okpomọkụ dị mma na nguzogide na-ekpo ọkụ na okpomọkụ nke 1550 Celsius, na okpomọkụ kachasị arụ ọrụ na-atụ aro bụkwa 150 Celsius C karịa nke TZM.Dị ka ihe atụ na extrusion nwụrụ, ọ nwere ike idi oké thermal na n'ibu ibu, otú MHC ihe na-atụ aro maka metal akpụ ngwa.

Molybdenum-zirconium alloy, nke ejiri obere zirconia (ZrO2) mee ya na molybdenum dị ọcha, nwere ike ịkwalite nguzogide corrosion na nguzogide molybdenum.

Na-agbakwụnye obere ihe n'ụwa nwere ike ọ bụghị naanị melite recrystallization okpomọkụ na elu okpomọkụ creep nguzogide nke molybdenum, kamakwa budata ibelata plastic-na-emebi emebi okpomọkụ nke molybdenum, dịkwuo ductility, na melite ụlọ okpomọkụ brittleness na elu okpomọkụ sag iguzogide molybdenum.

Ngwa

N'ihi ike ya dị elu nke okpomọkụ, elu recrystallization okpomọkụ na ezigbo thermal conductivity, TZM alloy na-ejikarị eme ihe na mbara igwe, ụgbọ elu na mpaghara ndị ọzọ, dị ka ihe mkpuchi, ihe mkpuchi, ahụ valve gas, pipeline gas pipeline.Enwere ike iji ya dị ka akụkụ anode nke na-atụgharị X-ray, ihe nkedo na-egbu egbu na ihe ọkpụkpụ extrusion, ihe ndị na-ekpo ọkụ na ihe mkpuchi ọkụ na ọkụ ọkụ dị elu.

MHC alloys na-ọtụtụ ebe eji metal akpụ ngwa:

● A na-ejikarị waya molybdenum na-adịghị ahụkebe eme ihe dị ka filament ọkụ ọkụ eletrik, electrode EDM na ihe ọkụ ọkụ dị elu.

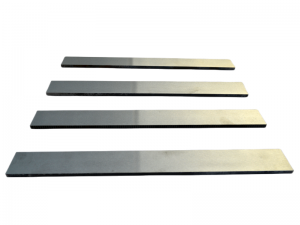

● A na-eji efere molybdenum na-adịghị ahụkebe mee ihe dị ka wafer maka ịkụnye thyristors, yana ọta okpomọkụ na mpempe akwụkwọ ntuziaka maka tubes electronic.

● Enwere ike iji alloy molybdenum na-adịghị ahụkebe mee ihe dị ka isi igwe na-ekpo ọkụ na-ekpo ọkụ, yana ikuku ikuku na ihe ụlọ ọrụ nuklia, ogwe osisi X-ray, ihe nkedo na-anwụ anwụ na extrusion na-anwụ.

● A na-eji ngwaahịa molybdenum na-adịghị ahụkebe mee ihe dị ka electrodes na-agbaze enyo, electrodes na-agbaze ụwa, ihe ndị na-emepụta ihe, ụgbọ mmiri na-ekpo ọkụ na-ekpo ọkụ, ihe mkpuchi okpomọkụ dị elu nke okpomọkụ, ọdụ ụgbọ mmiri na-asọpụta, okporo ụzọ nduzi, pads, wdg.

● A pụkwara iji alloys molybdenum na-adịghị ahụkebe mee ihe dị ka ihe cathode na-ekpo ọkụ maka ọkpọkọ eletrik na nke dị elu.The obere-earth molybdenum alloy thermal cathode ihe na-anọchi spallation tungsten cathode ugbu a, nke nwere oke ọrụ okpomọkụ, redioaktivu ofufe, na elu brittleness, na nwere ike dị ukwuu ibelata okpomọkụ ọrụ nke tube ma melite ntụkwasị obi.

Ndị mmeri Baoji na-arụpụta tungsten na molybdenum na ihe alloy ya ma nwee ike ịhazi ya iji gboo mkpa ndị ahịa.Maka ozi ngwaahịa ọzọ, biko kpọtụrụ anyị (Whatsapp: +86 156 1977 8518).

Oge nzipu: Ọgọst-02-2022